|  |

FRP Pressure Vessels ROPV offers a full line of pressure vessels ranging from 2.5 inch to 18 inch, covering all major industry system and application requirements with a maximum operating pressure up to 2000 psi with multiple side port configurations up to 4 inches. We continue to innovate with over twenty registered patents to date. ROPV has successfully developed numerous original equipment configuration with various industry partners for UF, EDI, large diameter membranes, and emerging water treatment technologies. |  |

Radome HARBIN TOPFRP COMPOSITE CO., LTD (TOPFRP) is one of the best suppliers of high performance radomes since 1980. The radomes made from FRP or metal frame with membrane with good “RF transparent” performance to protect radars and other antenna systems from wind, rain, snow, ice, blowing sand, salt, solar radiation, and freezing temperatures. Thousands of radomes from TOPFRP have been applied in domestic and 55 countries in the fields of Civil Aviation, Meteorology and SATCOM, etc. |  |

Filament winding machine Modular design meets various specifications needs, offering flexibility with control systems such as Siemens 828Dsl, 840Dsl, Sinumeric One or PMAC104 programmable controllers. The system supports up to 6 servo motion axes, ensuring precise fiber placement. User-friendly software simplifies operation, and the multiple spindle quantity design enhances efficiency. The system also includes data monitoring and display capabilities, with options for mechanical or electronic tensioners and different resin impregnation systems to suit various specifications. |  |

Composite communication tower The construction of communication tower is a national strategic layout, which is closely related to urban development and the quality of people's life. Composite communication tower with light weight, high strength, corrosion resistance and maintenance free can meet the fine technical requirements and strict application scenarios. We have advanced structural design and manufacturing technology, with the products ranging from 3 meters to 30 meters, more than 20 models, covering the domestic Heilongjiang, Guangdong, Guangxi, Yunnan and other provinces, and being sold to Egypt, Portugal, Bulgaria and other countries. The carbon emission of composite communication tower is 43% lower than that of metal tower, which is very much in line with the concept of green environmental protection. |  |

|

Glass-based special functional materials CBMA is a leading research institution and industrialization platform for glass-based functional materials in China, pioneering the core material fields such as passive interference materials, low-light-level night vision materials, and UV alarm materials. It has the earliest established production base for aviation glass and special glass in China, which offers the largest number of models and reaches the leading technological level. Furthermore, CBMA has established the only quartz glass research institution in China that integrates research, development, production, testing, and talent cultivation. It has overcome numerous significant challenges, and is the core R&D and production unit for passive interference materials, low-light-level night vision materials, UV alarm materials, special glass materials, quartz glass materials and other materials in China. Its core products have reached the international leading level, with the purity of quartz glass reaching 99.9999% and the fiber optic image transmission materials capable of high-fidelity transmission of photoelectric images. |  |

|  |

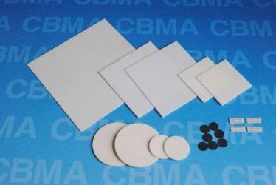

Oxide Structural Ceramics The performance of oxide structural ceramics with high strength and toughness, precision micro-hole processing and ultra-precision surface polishing, has reached an internationally advanced level. Oxide structural ceramics include large-size precision oxide ceramic substrates used in thin-film circuits, covering materials such as Al2O3, ZrO2, ZnO, and multicolor ceramics. These products are widely applied in the fields such as aviation, aerospace, electronics, shipbuilding and the nuclear industry. Furthermore, other developed structural ceramics such as Al2O3, ZrO2, fluorophlogopite mica, insulated machinable boron nitride, etc., have been widely used in sodium-sulfur battery units, nuclear power plants, solar polysilicon melting equipment, and other fields. |  |

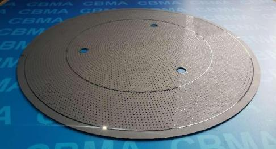

Silicon Carbide Components for Semiconductor Process Silicon carbide structural components including high-specific stiffness ceramic workpiece tables, gas bearing linear motion stage, measurement grating, vacuum chuck and other complex shape components, are used in the field of high-precision ceramic materials for ultra-large-scale and very-large-scale integrated circuit manufacturing equipment. MOCVD equipment produces graphite-deposited silicon carbide susceptors using chemical vapor deposition (CVD) technology, as well as high-purity sintered silicon carbide (SSiC) susceptors. These products are critical for semiconductor silicon wafer production in LED manufacturing, with their performance approaching the international advanced level. |  |

New Energy Battery Material Equipment Xianyang Research and Design Institute of Ceramics Co., Ltd. specializes in the production of various equipment such as rotary furnaces, roller furnaces, and atmosphere push plate furnaces. Among them, the rotary furnace adopts advanced rotary dynamic drying and calcination technology, which is widely used in multiple fields such as lithium battery cathode materials and precursors. The designed 10,000t lithium battery negative electrode material kiln has achieved an increase by 30% in diameter and 40% in length, while reducing energy consumption by 15%, saving more than 20% in costs for customers and winning widespread praise in the industry. The roller furnace is continuously heated, with a temperature of up to 1,350℃ and a high degree of automation. The size of the atmosphere push plate furnace can be customized, with a maximum temperature of 1,600℃, fast heating, accurate temperature control, many advantages, easy operation, low maintenance cost, and great popularity. |  |